During the summer of 2016, I had the opportunity to conduct a research project under the supervision of Professor Andrew Kirk and Dr. Philip J. Roche as part of the Summer Undergraduate Research Experience (SURE) at McGill University.

The ultimate goal of the project was the development of a novel PCR Machine that could complete a DNA replication in less than a minute. This, when combined with DNA based sensors, would allow for the rapid detection of various illness and be a useful diagnostic tool for doctors.

The heating mechanism for the PCR reaction was gold nanorods and lasers. Gold nanorods were inserted into the PCR solution and a laser was shone on the reaction vessel. The gold nanorods absorbed the energy from the laser and then radiated it as heat. This allowed for very rapid heating.

The first task of the project was to develop a procedure to produce large quantities of nanorods with a peak absorbance at the frequency of the laser. This was done by reviewing the literature associated with the production of gold nanorods and experimentation.

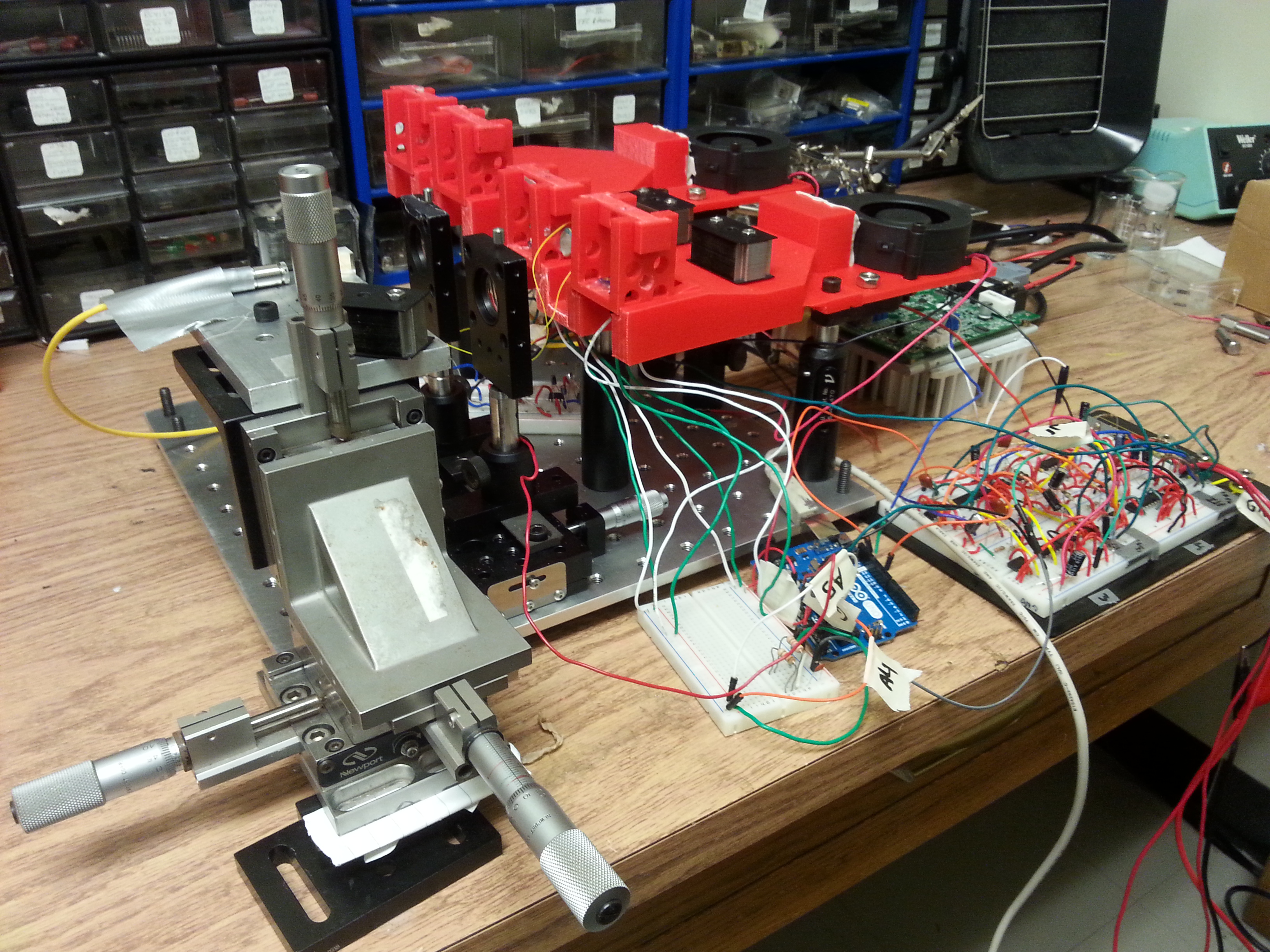

Once the gold nanorods had been produced, the next task was to begin building the system itself. A double sample holder was designed using CAD software and then 3D printed. The sample holder also had a space for a fan, to help to cool the sample. The holder was mounted on an optical breadboard with the laser and a beam splitter system.

The circuitry for the system was worked on next. The system was controlled using an Arduino Uno microcontroller. The Arduino allowed the laser and fan to be turned on and off, control the power, measure the temperature of the samples via thermopiles mounted on the sample holder and the signal from a homemade lock in amplifier.

The lock in amplifier was connected to a simple absorbance measuring system built into the sample holder and was used to eliminate noise in the signal produced by a photodiode. Light from a low power laser was passed through the sample perpendicularly to the heating laser and onto a photodiode. The signal produced by the photodiode was proportional to the transmission of the sample at the frequency of the low power laser. This system allowed a shift in the absorbance spectrum of the sample, which would result from DNA sensors included in the sample vessel in the final PCR device.

Further steps in the development would have been to implement a PID controller to control the laser and fan (the heating and cooling) to achieve rapid thermocycling needed for the PCR reaction, and to functionalize the gold nanoparticles with DNA based sensors, but unfortunately the summer was coming to a close.

At the end of the summer, a research poster was presented to members of the university, alumni and guests at a poster presentation. The posters presented are provided here (this project was done in a team of two, so we had two posters).